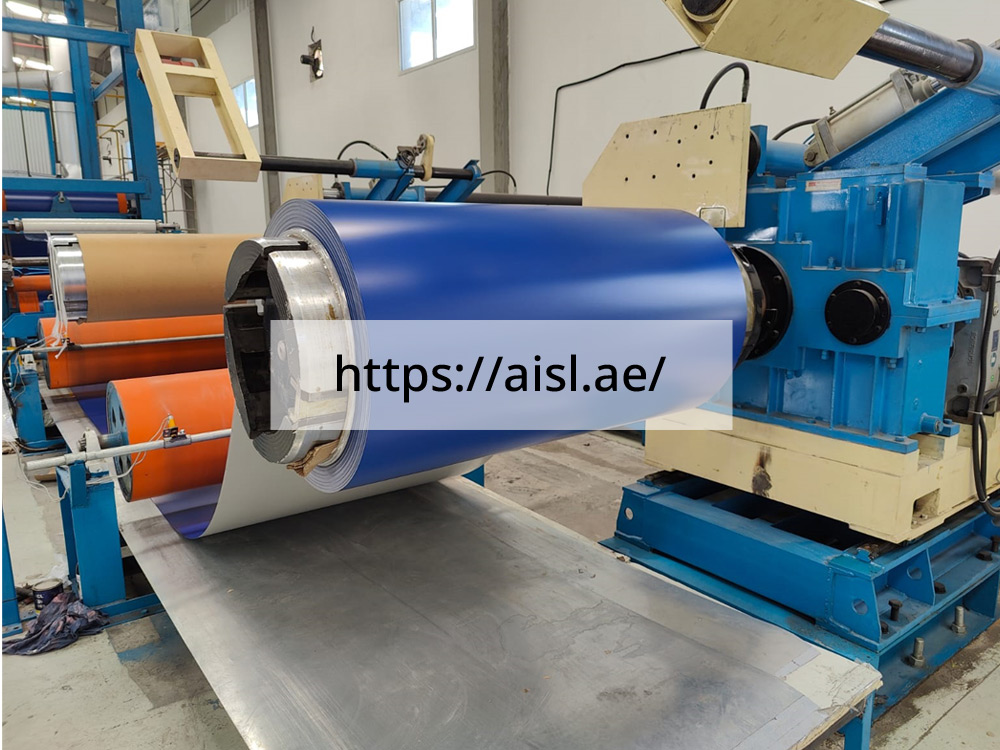

PREPAINTED ALUMINUM COILS (PPAL)

Arabian Iron and Steel LLC is one of the leading manufacturers & exporters of high-quality Pre Painted Aluminum Coils in Dubai as per International Standards & Specifications.

Pre-Painted Aluminum Steel Coils

Pre-Painted Aluminum Steel Coils & Pre-Painted Galvalume Steel Coils are widely used in many sectors worldwide.

What are PPAL coils?

Pre-Painted Aluminum Steel Coils (PPAL) are widely used in many sectors worldwide. PPAL coils are pre-painted aluminum coils coated with a colorful, protective layer. They're durable, corrosion-resistant, and easy to shape. Ideal for construction, automotive, and consumer goods. The uses of prepainted aluminum are many and varied and are increasing daily in the Industrial, commercial and residential industries.

01

01

Pre-Painted Aluminum Steel Coils

Pre-Painted Aluminum Steel Coils & Pre-Painted Galvalume Steel Coils are widely used in many sectors worldwide.

PPAL coils and coil coating

High quality Pre Painted Aluminium Coils in Dubai as per International Standards & Specifications.

Specficiation

- Thickness: 0.20 mm to 2.0 mm, Width 20 mm to 1220 mm, Coil / Sheet

- Alloy : 3105, 3003, 1100 or any as per customer requirement

- Temper: H14, H16, H24, H46 or as per customer requirement

- Standard: ASTM B209 or Equivalent, Origin : India / Bahrain / China / Oman

APPLICATION

Aluminium strips and coils are common materials with many advantages. Aluminium strips and coils have good forming performance and corrosion resistance, used in transportation, automobile, shipbuilding, instrument, electrical enclosure, etc. Some uses of pre-painted aluminium sheets made out of the coils are:

| Aluminium strips and coils are | |||

|---|---|---|---|

| Metal roofing | Garage doors | Heating and air conditioning | Office furniture |

| Automotive and transport industry | Bakeware | Lighting envelopes | Factory shades |

| Wastorage | Cold storages | Appliances | Interiors |

| Construction | Packaging | HVAC | Furniture |

| Service Centers | Architects sector | Heavy machinery | Aviation |

Features of pre-painted aluminum coils

This also includes design flexibility. It has environmental advantages as compared to other materials. Pre-painted aluminium is a sustainable choice as it can be recycled.

Our pre-painted aluminium sheets not only enhance productivity but also save costs on manufacturing, energy, finance, and inventory. These coils are used in various commercial and public buildings.

The natural anti-corrosive property of aluminium when combined with paint coatings enhances the appearance and adds more strength, durability, and resistance against corrosion, rust, and harsh weather systems.

Coil coating system

Coil coating is a very creative and efficient way to produce a uniform, high-quality, coated finish over metal in a continuously automated style. Coil coating is also pertained to as pre-painted metal, because the metal is painted before, rather than after the fabrication.

In the coil coating process, the metal coil is initially unwound, cleaned, pre-treated, applied on a flat continuous sheet, heat cured, cooled, and rewound for cargo. At the fabricator, it is then cut to the requisitioned size and formed into its final shape. Coil coating efficiency is nearly 100% more productive than other application methods because in a single consecutive process both the top and bottom sides are cleaned, chemically treated, primed, oven-cured, top coated, oven-cured again, rewound, and packaged.

Coil coating provides beautiful topcoats, durable surfaces, innovative applications, and cost savings as compared to other membrane or other coating options.

Coating systems supplied as per the specification comprise a two-coat covered by various types and thicknesses of top coats. The assortment of primer and top coat is classed as either a two-coat thin-film system or a multi-coat thick-film system.

We Can produce wide range of RAL color like below or any other customized.

RAL 7037 – Grey, RAL 1014 – Light Beige, RAL 1015 – Ivory, RAL 9002 – Off White, RAL 1001 – Beige, RAL 2004 – Orange, RAL 7015 – Grey, RAL 7036 – Grey, RAL 5012 – Light Blue, RAL 5010 – Dark Blue, RAL 5002 – EMMAR Blue, RAL7046 – Dark Grey, RAL 9003 – White, RAL 9010 – Pure White, RAL 3002 – RED, RAL 3020 – RED, RAL 6038 – Green, RAL 6029 – Light Green and other color choices

AISL is able to process different types of Coloor coating by using Aluminium , Alu Zinc, Aluminium Mill Finish coil as Finish coating called, RMP (Regular Modified Polyester), Plasto (Plastisol Smooth Finish up to 220 Microns), Plasto Leather (Plastisol Leather Finish Coating up to 210 Microns), HDPE (High Durable Polyester), SMP (Silicone Modified Polyester), Ultra (PVDF Kynar 500- 2/3/4 Layer Coating up to 120 Microns), Hygiene (Anti-Bacterial Coating), Endura Anti-Corrosive Primer with Urethane / Epoxy Coating- multiLayer Coating up to 170 Microns), Acry (Acrylic Coating), PMMA (Polymethyl Methacrylate Coating) ARS (Polyurethane Polyamide / Abrasion Resistance System), TOC (Thin Organic Coating), Wrinkle (Anti-Dust / Anti-Skidding System), EcoFresh (Self Easy Cleaning), Polyester Texture Finish - Terracotta

The process at a glance

In short, the coil coating process is a method of applying an organic coating element on rolled metal strip substrate in a continual process. This process includes:

- Unwinding the coil and cleaning, if necessary

- Chemical pre-treatment of a metal surface of either one side or two sides

- Single or multiple applications of liquid paints or coating powders which are thereafter cured or laminated with plastic films

- Cooling and rewinding the same coil for shipment to a sheeter, a slitter, or a fabricator

All coil coating lines from the traditional and most basic line to the newest and most modern line have numerous common steps or processes. Coil coating technology in recent years has grown more rapidly than more conventional application technologies due to a variety of benefits that encompass cost savings, versatility, environmental, performance, and quality issues.

Our market

Arabian Iron and Steel LLC provides the best quality Coated steel and Aluminum to our valued customers across the UAE, GCC, Africa, and South Asia– especially the USA and Canada, and EU.

Pre-Painted Aluminum Steel Coils are available in PPGI Coils / Sheet or PPGI Slit Coils in Dubai – UAE and all over Oman (Salalah, Muscat, Sohar, Nizwa, Barka, Ibri) | Saudi | Iraq | Kuwait | Bahrain | Yemen | Sri Lanka | Jordan

Why AISL

In short, the coil coating process is a method of applying an organic coating element on rolled metal strip substrate in a continual process. This process includes:

Arabian Iron and Steel LLC offers you a variety of steel products to satisfy all your requirements. We adhere to quality management requirements and continuously improve our systems and product quality. By combining the latest innovative technologies in manufacturing, efficiency, and sustainability, we produce the high-quality products, services, and solutions that are needed to satisfy our valued customers.

test