Galvanized Steel Coil

Hot dipped galvanized steel Coil or Sheet is manufactured by passing cold rolled steel through a molten bath of Zinc at temperatures around 460 °C. The Zinc coating acts as a robust physical barrier between the atmosphere and the surface of the metal. Further, due to its lower chemical potential than iron, it is attacked and dissolved first, thereby offering superior corrosion resistance (cathodic protection).

SURFACE FINISH & COATING THICKNESS

Galvanized steel can be identified by the crystallization pattern on the surface (often referred to as "spangle"). Regular, Minimized and Suppressed Spangle are the three types of surface finishes that are available. The service life of this material would depend on the coating thickness, which is available between 60 to 350 grams per square meter.

GI Applications

GI has a wide variety of applications which include Roofing, Sidewall Partitions, False Ceilings, Decking, Steel Buildings, Automobile Components, Water Heater and Coolers, Furniture, Rolling Shutters, Sign Boards, HVAC Ducting and many more.

Galvanized steel Advantage

- Superior corrosion resistance

- Higher aesthetic value

- Excellent workability and adherence to paint

Hot Dip Galvanized (GI ) Steel Coil / Sheet/ PRODUCT TYPE AND APPLICABLE SPECIFICATION

| DESCRIPTION | GALVANIZED STEEL |

|---|---|

| SPECIFICATION | ASTM A 653 / A 653 M - 18 CS TYPE A, B, C FS, DS, HTS SS GRADE 33,37,40,50,80 EN 10346: 2015 Which Supersedes EN 10327 : 2004 DX 51 D, DX 52 D, DX 53 D EN 10346: 2015 Which Supersedes EN 10326 : 2004 S220 GD, S250 GD, S280 GD, S320 GD, S 350 GD, S 550 GD JIS G 3322 : 2010 SGCC, SGCD1, SGCD2, SGCD3, SGC : 340, 400,440,490,570 |

| TYPE | Tension Levelled / Non Tension Levelled Skin Passed / Non Skin Passed |

| SURFACE FINISHED | Regular Spangle / Minimized Spangle / Suppressed Spangle |

| SURFACE TREATMENT | Chromate passivated (Cr+6 / Cr+3), Non-Chromate passivated, Oiled , Non Oiled, No Treatment |

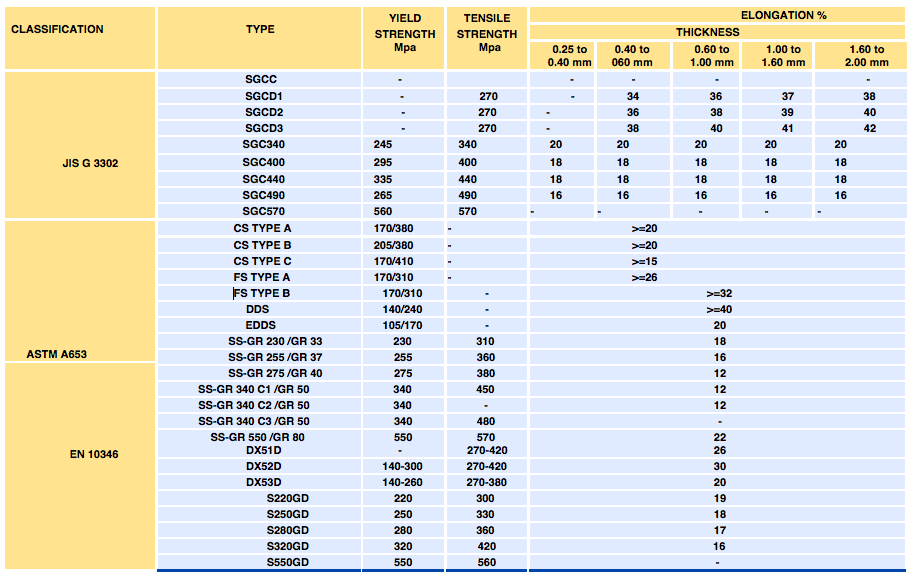

TTYPICAL RANGES OF MECHANICAL PROPERTIES

Galvanized steel