Aluzinc Steel Coil

Aluzinc is composition of coating 55% aluminum, 43.4 % zinc and 1.6 % silicon. The coating is also applied by means of a continuous hot dip galvanizing process. Aluzinc-zinc coating offer an excellent corrosion resistance resultant from the barrier effect of the aluminum on the surface and the sacrificial protection of zinc. Aluzinc has a clean, natural and bright silvery surface. The surface includes small spangles that give it a lustrous and striking appearance as light conditions change.

Aluzinc is the world's fastest growing metallic coating. This is due to the fast of combined strength, formability and recyclability of steel with the proven long term anti-corrosion performance of the Al-Zn alloy coating. This combination results in an economical product with superior eco-friendliness attributes of durability, recyclability, energy efficiency and scarce resource utilization.

Corrosion Resistance

The improved corrosion resistance of 55% Al-Zn alloy- coated steel coils is derived from the unique combination of the barrier protection of the aluminum and the sacrificial protection of the zinc. The formation of an insoluble aluminum oxide layer provides the barrier protection, while the zinc provides a sacrificial protection at cut edges, scratches and areas of coating damage.

Heat Resistance

Similar to the aluminum coated steel that can resist high temperature -oxidation, 55% Al-Zn alloy-coated steel demonstrates better resistance to high temperature.

Heat Transmission and Reflectivity

55% Al-Zn alloy-coated steel coil has a high reflectivity value making it an effective barrier against heat.

Product Type and Applicable Specification

| DESCRIPTION | ALUZINC |

|---|---|

| SPECIFICATION |

ASTM A 792 / A 792 M - 10 (2015) CS TYPE A,B,C FS,DS,HTS SS GRADE 33,37,40,50,80 EN 10346: 2015 Which Supersedes EN 10326 : 2004 DX 51 D , DX 52 D, DX 53 D EN 10346: 2015 Which Supersedes EN 10327 : 2004 S 220 GD, S250 GD , S320 GD, S 350 GD, S 550 GD JIS G 3321 : 2010 SGLCC, SGLCD , SGL : 400,440,490,570 |

| TYPE | Tension Levelled / Non Tension Levelled Skin Passed / Non Skin Passed |

| SURFACE FINISHED | Regular Spangle / Minimized Spangle / Suppressed Spangle |

| SURFACE TREATMENT | Chromate passivated (Cr+6 / Cr+3), Non-Chromate passivated, Oiled , Non Oiled, Anti-Finger print, Non Anti-Finger Print and No Treatment |

COMPARABLE INTERNATIONAL GRADES

| CLASSIFICATION | ASTM A 792-10(2015) | EN 10346 : 2015 | JIS G 3321 :2010 |

|---|---|---|---|

| COMMERCIAL QUALITY | CS | DX51D | SGLCC |

| LOCK FORMING QUALITY | CS | DX51D | SGLCC |

| DRAWING QUALITY | FS | DX52D | SGLCD |

| DEEP DRAWING QUALITY | DS | DX53D | SGLCD |

| STRUCTURAL QUALITY | GRADE 230-550 | S220-S550 | SGL 400 - 570 |

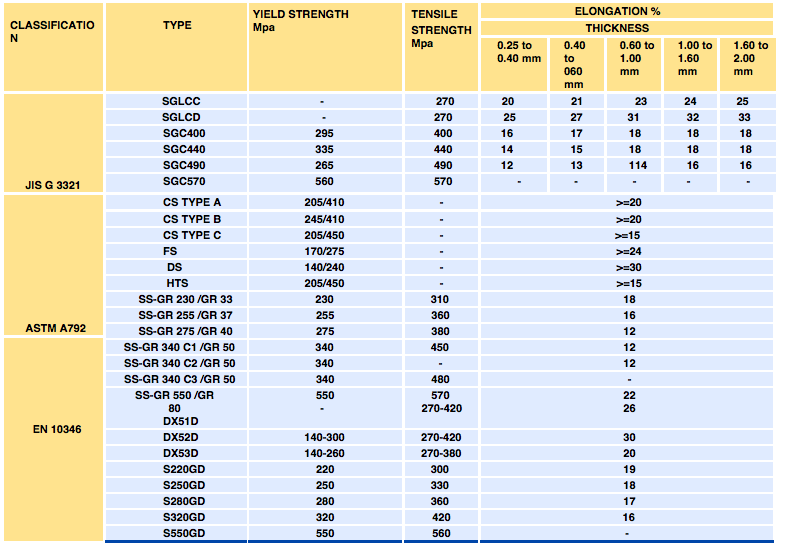

TYPICAL RANGES OF MECHANICAL PROPERTIES

extra