Pre-coated steel in the UAE and the broader Middle East is a technological marvel in the realm of construction materials and has become an integral choice for architects and engineers. This innovative material undergoes a meticulous process where protective coatings are applied to the steel substrate before it reaches the construction site. The coatings serve as a formidable shield against the harsh environmental conditions prevalent in the region, including scorching temperatures, sandstorms, and corrosive elements. This method not only enhances the structural durability of the steel but also bestows it with resistance to corrosion, UV radiation, and other forms of degradation. The versatility of pre-coated steel allows for a wide range of applications, from towering skyscrapers to intricate infrastructure projects.

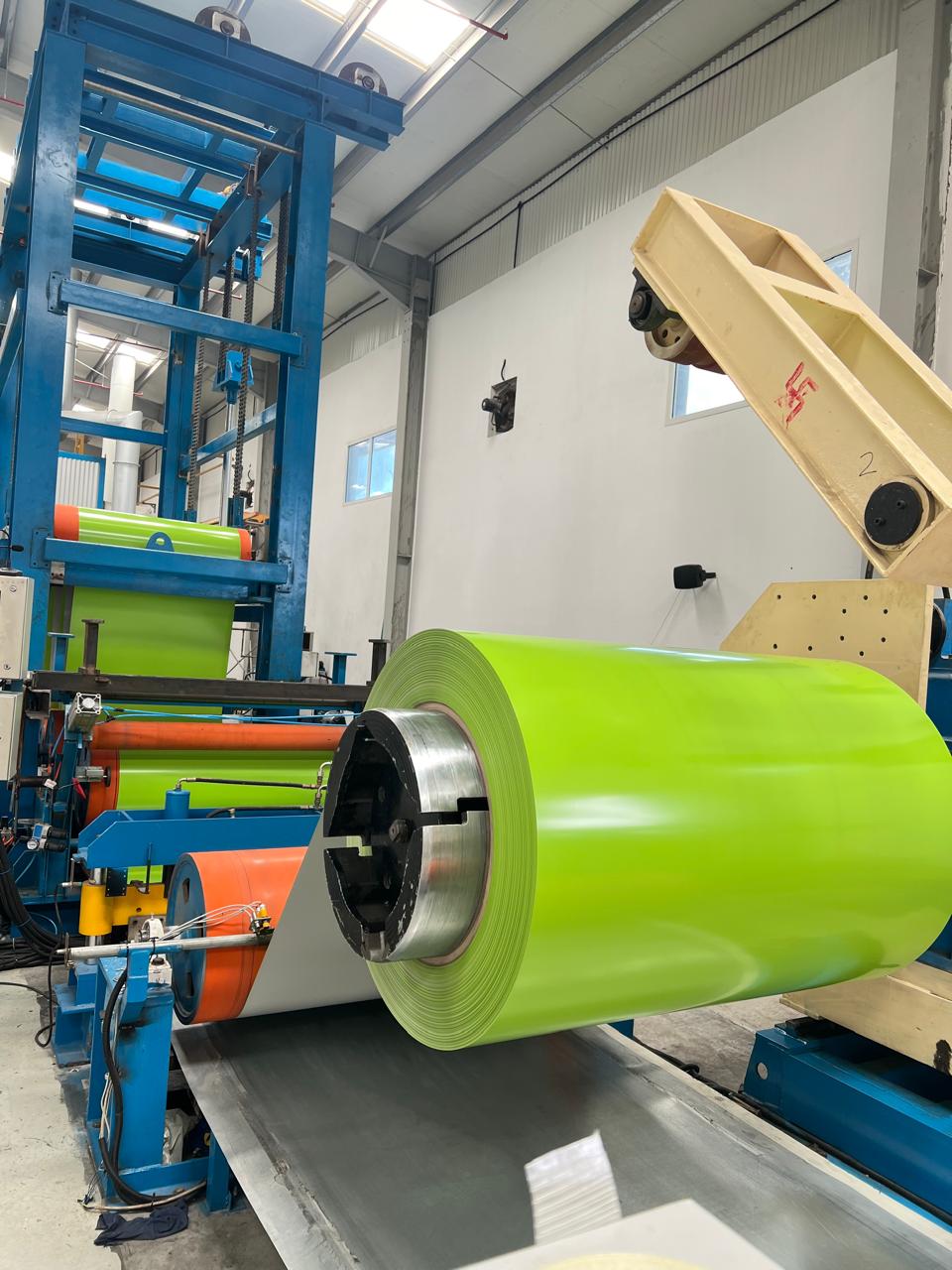

Process of making precoated steel

The process of making pre-coated steel involves several carefully orchestrated steps, ensuring the steel substrate receives a protective coating before being employed in construction. Here is an overview of the key stages:

Surface Preparation:

The process commences with the thorough cleaning and preparation of the steel surface. Any impurities, rust, or contaminants are removed to create an optimal foundation for the subsequent coating layers.

Chemical Pre-Treatment:

The cleaned steel undergoes a chemical pre-treatment to enhance its adhesion properties. This step often involves applying a conversion coating that improves the bonding between the steel surface and the subsequent coating layers, promoting long-lasting adhesion.

Primer Application:

A primer coat is then applied to the treated steel surface. The primer serves as the initial layer of protection, offering corrosion resistance and improving the overall durability of the steel. The choice of primer depends on the specific requirements of the end application and the environmental conditions the steel will face.

Application of Base Coat:

Following the primer, one or more base coats are applied. These base coats provide additional protection, often incorporating pigments to achieve specific colour requirements. The selection of base coat formulations considers factors such as UV resistance, weather resistance, and aesthetic preferences.

Top Coat Application:

The final layer, known as the top coat, is applied to the base-coated steel. This layer acts as a protective barrier, shielding the steel from environmental factors such as UV radiation, moisture, and pollutants. The top coat also contributes to the material's visual appearance and can be tailored to achieve desired colours, textures, and finishes.

Curing and Drying:

After the application of each coating layer, the pre-coated steel undergoes a curing process. This step allows the coatings to chemically bond and solidify, ensuring optimal performance. The steel is then thoroughly dried to complete the curing process.

Quality Control and Inspection:

Rigorous quality control measures are implemented throughout the entire process. Inspection criteria include adhesion strength, coating thickness, colour consistency, and overall coating integrity. This meticulous scrutiny ensures that the pre-coated steel meets industry standards and specifications.

Packaging and Transport:

Once the pre-coated steel passes quality control checks, it is carefully packaged to prevent damage during transport. The material is then ready for distribution to construction sites, where it will be utilized in an array of architectural and structural applications.

Understanding the Environmental Challenges:

The Middle East, with its arid climate and high temperatures, poses unique challenges to building materials. Explore how Pre-coated steel in the UAE and the broader Middle East addresses these challenges and serves as a resilient choice for structures subjected to intense sunlight, sandstorms, and occasional moisture.

Advantages of Pre-Coated Steel in the UAE Context:

Examine the specific advantages that pre-coated steel brings to construction in the UAE, such as corrosion resistance, UV protection, and its ability to withstand temperature fluctuations. Showcase real-world examples of projects that have stood the test of time.

Routine Inspection Protocols:

Establish the importance of regular inspections to identify potential issues early on. Detail a comprehensive inspection checklist covering aspects like coating integrity, surface corrosion, and any signs of wear and tear. Emphasize the role of preventive maintenance in avoiding costly repairs.

Cleaning and Surface Maintenance:

Provide step-by-step guidance on cleaning pre-coated steel surfaces to maintain their aesthetic appeal and protective properties. Highlight suitable cleaning agents and techniques that are effective in removing dust, pollutants, and other contaminants without compromising the coating.

Corrosion Prevention Strategies:

Explore various strategies to prevent and mitigate corrosion, focusing on both the coating and the steel substrate. Discuss the importance of selecting high-quality coatings and the role of cathodic protection in enhancing the lifespan of pre-coated steel structures.

Repair and Refurbishment Techniques:

Inevitably, pre-coated steel structures may face wear and tear over time. Detail effective repair and refurbishment techniques, ensuring that the structural integrity is maintained while addressing any cosmetic or protective issues.

Climate-Responsive Maintenance Plans:

Tailor maintenance plans to the seasonal variations and extreme weather events typical in the Middle East. Discuss specific considerations for each season and how proactive measures can mitigate the impact of harsh conditions.

Compliance with Standards and Regulations:

Emphasize the importance of adhering to local and international standards for pre-coated steel maintenance. Provide insights into the regulatory landscape in the UAE and how compliance ensures the safety and longevity of structures.

As a testament to its reliability, structures with Pre-coated steel in the UAE and the broader Middle East, not only meet the stringent demands of the climate but also contribute to sustainable construction practices, offering a balance between strength, aesthetics, and environmental consciousness.

The longevity of pre-coated steel structures in the UAE is a result of a proactive and well-executed maintenance strategy. By understanding the environmental challenges, implementing routine inspections, and following best practices for cleaning, corrosion prevention, and repairs, stakeholders can ensure that these structures continue to stand strong against the elements for years to come.

Arabian Iron and Steel LLC offers you a variety of steel products to satisfy all your requirements. We adhere to quality management requirements and continuously improve our systems and product quality. By combining the latest innovative technologies in manufacturing, efficiency, and sustainability, we produce the high-quality products, services, and solutions that are needed to satisfy our valued customers.